With the rapid implementation of China’s “plastic ban,” everyone is choosing better alternatives to meet their packaging or product needs. Plant fiber molding products are an ideal cost-effective solution. The raw materials we choose are made of 100% plant fiber, recyclable, biodegradable, and we even reuse the water that makes the pulp. Plant fiber molding products base materials, additives, and paper the same, the process is very close, but plant fiber molded products are formed on the net.

When the plant fiber passes through the mesh mold, the fiber is intercepted by mesh mold, and the water is filtered out. The pulp fiber (plant fiber) forms a wet paper blank by hydrogen bonding between fibers. The wet paper blank is then dried or heat set and finally becomes a plant fiber molded product. These are the plant fiber molded products forming the basic process.

For the base material of plant fiber molding products, different kinds of plant fibers also have different advantages and disadvantages, our engineers have made the following summary:

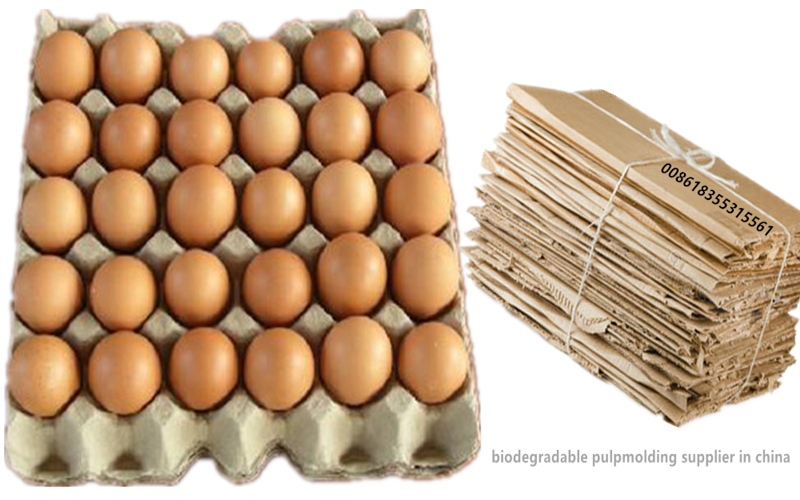

Ordinary waste paper pulp molding (plant fiber molding) products.

Refers to the molding products that are made by the yellow pulp of cardboard boxes, newspaper pulp, or A4 pulp, price and hygiene requirements are low, commonly used egg tray, fruit holder, internal buffer packaging are generally used with these raw materials.

Sugar cane pulp molded (plant fiber molding) products.

After biological pulping, the wet pulp or pulpboard will be crushed, reforming and shaped to molding products. Sugar cane fiber is long fiber, possesses the advantages of moderate intensity and toughness. Currently, it’s the most suitable raw material for molding products, therefore, sugarcane pulp products are the most widely used currently. At present, sugar cane fiber is used in meal boxes, tableware products mainly, and some high-end mobile phone holders, cosmetics packaging also use this kind of raw material.

Wheat straw pulp molded (plant fiber molding) products.

At present, the annual output of straw in China has exceeded 80 million tons, of which about 7 million tons of recycled straw resources; About 15.0% of recyclable straw resources are returned directly to the field, about 30.7% are used to produce animal feed, and about 17.9% of industrial energy, Only 5.25% were used in other project areas such as material preparation, and about 2.6% of them were used as industrial raw materials such as paper making. The proportion of straw resources directly discarded and burned was as high as 31.6%.

Include the mechanism of fiber wheat straw pulp molding products, chemical machinery wheat straw pulp molding products, and chemical wheat straw pulp molding products. Wheat straw fiber is short, has good stiffness, the product is very fragile, poor flexibility. Generally, need to mix long fiber in the production process, and increase the toughness of the products. It is mainly used for the coffee holder, dry pressed products, and there are also cases of making tableware boxes with bleached and primary color straw fibers. In addition, straw fibers also have cases of making seedling holders, fruit trays, and seedling trays.

Bamboo pulp molded (plant fiber molding) products.

Bamboo fiber belongs to the medium-length fiber, the performance between coniferous wood and broadleaf wood. Bamboo pulp products have the advantage of strong toughness, and smooth surface, but it’s easy to have fluffy wool fibers, it can be added to the production of goods with a complex shape, slope, and smaller R Angle. At present, bamboo fiber is used with sugarcane fiber together mainly, especially for making compostable tableware.

Wood pulp molded (plant fiber molding) products.

Mainly divided into coniferous wood pulp and broad-leaved wood pulp, coniferous wood pulp fiber is long and thin, is relatively pure, and has fewer impurities. Broad-leaved wood pulp fiber is coarse and short and contains more impurities, the strength of the finished product is relatively low, and the finished product is relatively loose with strong absorption performance, high opacity. The paper made from coniferous wood pulp has good flexibility, high folding resistance, and better tensile strength. The paper made from broad-leaved wood pulp has high stiffness with high bulk and good packaging performance. Therefore, the thickness and density of products produced by different wood pulp will be different. Poplar pulp and eucalyptus pulp is also used in tableware, high-grade egg tray, and high-grade coffee holder production.

Reed pulp molded (plant fiber molding) products.

Mainly used for paper making, molding products used in low-grade products, the reed section is not easy to remove during the process of reed pulp production, impurity is more, and white degree is low. But the price is low, and drainability is better because the fiber is bulgy, so the thickness is thicker compare with the same weight product and takes up larger space for stock.

Palm pulp molded (plant fiber molding) products.

Refers to the products that are made from the fiber extracted from palm fruit and palm leaf, this type of pulp is used rarely, because the palm oil content is high, and not easy to remove, even though the product has good stiffness.

Vines, ramie cotton pulp molded (plant fiber molding) products.

Vines pulp is used in a general sense, yellow flower vine, towel gourd stem, and various melon plants can be used in the production of molding products, but different types of fiber can make a big difference, this kind of fiber belong to short fibers mostly, stiffness is poorer, and the impurity is not easy to handle, therefore has not been used widely.

Cotton rod pulp molded (plant fiber molding) products.

Use cotton rods only, products made from the intermediate tissue of the cotton rod, after removing the surface layer. The fiber of cotton rod fiber molding products is relatively fluffy, stiffness is poor, and used in low-grade paper making mostly.

Agricultural and forestry waste pulp molded (plant fiber molding) products.

Using the method of grinding to disperse the plant fiber raw materials into the fiber, under the action of mechanical force, the pulp produced by this kind of method is called the mechanical pulp. Mechanical molding fiber does not break away from lignin and cellulose, fiber binding force is poor, need to use with chemical pulp together, and the added amount of mechanical molding fiber should not be more than 50%, otherwise, the products will be easier to chip.

Chemical pulp molded (plant fiber molding) products.

Refers to the molding products that are made through acid and alkali pulping processing after chemical treatment, these kinds of products are delicate and smooth, beautiful. The disadvantage is that the cost is higher.

Rice straw pulp molded (plant fiber molding) products by biological process.

The biggest advantage of biological pulping is the small environmental load, which meets the long-term demand for low carbon environmental protection in China. At present, the technology is still in the process of maturity. There are some cases of making seedling trays, seedling substrate trays with water conservation in the desert, and seedling support with biological straw fiber.

For more details, please contact UV Tableware for an in-depth discussion, thank you.